Choosing the right irrigation system and equipment

Most specialty crop farmers in Minnesota operate on a relatively small scale (less than 50 acres) and thus rely on either drip irrigation or overhead sprinklers. Information about larger-scale irrigation systems such as center pivots can be found on the crops section of the UMN Extension website.

The choice between drip irrigation and overhead sprinklers may be influenced by farm size, crops grown, soil type, drainage or erosion potential, water supply, labor availability and up-front costs. Some farms may choose to use both.

This page covers materials needed for both drip and overhead irrigation systems, including components for filtering, pressure regulation, and injecting fertilizers and acids into your irrigation water. For information about irrigation scheduling, see Irrigation strategies for vegetable growers.

Drip irrigation

Pros:

- Drip irrigation is the most efficient way to irrigate crops. It delivers water directly to plant roots and reduces the amount of water lost to evaporation.

- Water is applied at the base of plants, which reduces standing water and humidity in the canopy. This can reduce plant disease pressure.

- By irrigating only in rows where crops are growing, drip irrigation can reduce weed pressure.

- Once installed, irrigating with a drip system reduces the time spent moving sprinklers around the farm.

- Soluble fertilizers can be efficiently added to your irrigation water with a drip system.

- Reduces energy requirements because low pressures are required.

Cons:

- Drip irrigation has a high up-front cost and requires significant labor at the beginning of each season for installation.

- Drip tape becomes clogged, often after only one season in Minnesota due to hard water. It must be replaced often.

- Agricultural plastic recycling is not consistently available in Minnesota, and thus this system produces significant plastic waste.

- If drip tape is not buried, it can easily get in the way of tasks like cultivation.

Drip irrigation systems require pressure regulators at the top of each sub-main line or header line. This is the line that spans each field, to which each individual line of drip tape is attached. This sub-main line is usually connected to a primary irrigation line that runs through the farm.

Using a pressure regulator reduces the water pressure to a level that will not blow out individual lines of drip tape.

A common mistake that farmers make is to place the pressure regulator too close to the well, thus decreasing pressure for the whole farm. Instead, place pressure regulators at the top of each field or tunnel, just before the point where you begin to attach lines of drip tape to your main line.

The pressure regulator you choose should be based on the flow rate. Some regulators are designed for low flow rates (5 gpm or less), and some are designed for much higher flow rates (10-30 gpm). The ideal water pressure for drip tape at the entrance of each field is typically 20-25 PSI. For overhead sprinklers, a higher PSI is needed, typically around 50-80.

There are many types of drip tape in the market with three general distinctions: tape thickness, emitter spacing, and diameter.

Tape thickness: Drip tape thickness generally ranges from 4 MIL to 25 MIL.

- Farmers who plan to use their drip tape for only one season tend to use 8-10 mil tape.

- Heavier products are more expensive but can be used longer if they do not clog.

- Many Minnesota farmers have hard water, and therefore have issues with clogging drip tape if it’s used for more than one year.

Emitter spacing: Drip tape has emitters (holes to release water) every 4 to 24 inches.

- Closer spacing allows more water to be released per minute. This flow rate is typically expressed as gallons per minute (gpm). A higher flow rate requires more pressure, which may or may not be compatible with your system.

- In Minnesota, 12-inch emitter spacing is fairly common.

- Test different spacings in your soil; especially in sandy soils, wider spacing may result in gaps where water is not reaching the soil.

Diameter: 5/8-inch diameter drip tape is fairly standard. For growers with very long rows (more than 500 feet), a wider diameter tape may be necessary.

Overhead sprinklers

Pros:

- Overhead sprinklers may require less up-front and ongoing investment than drip irrigation systems.

- Sprinklers do not produce as much waste; nozzles are the only part of the system that need to be cleaned or replaced with some regularity due to clogging.

- Overhead sprinklers can be easy and fairly quick to move from field to field.

Cons:

- Overhead irrigation is less efficient overall, with more water lost to evaporation.

- Water applied overhead results in more leaf wetness and canopy humidity, which contributes to the spread of disease.

Overhead sprinklers on vegetable farms typically consist of some combination of hard PVC plastic (either buried or aboveground), aluminum piping, and soft “layflat” tubing, eventually connecting to sprinkler heads. These sprinkler heads are typically raised 3-4 feet from the ground and can be capped with various nozzles.

Some growers use filters at the point at which the main irrigation line connects to the line containing sprinkler heads. Others do not, and simply watch for clogged nozzles.

Some common kinds of overhead sprinkler irrigation systems used in horticulture crop production are hand-moved sprinklers, solid set sprinklers, hand-moved big guns, traveling big guns and center pivot irrigation.

See in-depth information about each of these sprinkler systems from Penn State.

When choosing a sprinkler package for your irrigation system, it's important to understand the infiltration capacity of the soil in the field as well as cultural practices such as tillage and residue management.

Relevant soil information includes soil texture, infiltration rate, water holding capacity and slope.

The sprinkler should be able to apply water in a uniform manner while reducing runoff, evaporation and wind drift. Care should also be given to the sprinkler spacing and height for maximizing uniformity.

Some common types of nozzles used by vegetable farmers in Minnesota include:

- Wobblers: Wobbler sprinklers emit fairly large droplets that mimic gentle rain. They are one of the most common nozzles used by vegetable farmers, and they are named for their “wobbling” motion. Larger droplet sizes help to minimize losses from evaporation and wind drift. Water is applied slowly and with very uniform coverage while minimizing soil compaction.

- Rotating sprinklers: Rotating nozzles are also very common among vegetable growers. These nozzles deliver water in a rotating stream, which generally allows for a larger coverage area than wobbler sprinklers. A diffuser breaks up the water stream to distribute droplets. Rotating nozzles designed for vegetable farmers have gentle droplets, similar to those produced by wobblers, so water is applied slowly and with uniform coverage while minimizing soil compaction.

- Impact sprinklers: These sprinkler heads are driven in a circular motion by the force of outgoing water. The “arm” gets pushed back into the water stream with a spring mechanism, and the collision of the arm with the water scatters the droplets. This is an older technology, but these nozzles are still common. One benefit of them is that the water can be directed in one direction rather than around the full radius of the sprinkler, which may be optimal for certain field orientations.

For each of these sprinklers, manufacturer's literature can provide you with expected throw diameter and nozzle sizes. For example, the Nelson Irrigation Corp. literature for R2000WF rotator sprinkler shows a range of plate and nozzle options and flow performance in gallons per minute for different operating pressures.

Irrigation main line materials

Layflat tubing is light and flexible. However, it is also prone to leaks. It is made out of flexible PVC plastic, and comes in diameters ranging from 1.5” to 6”. Some farmers use this as their primary irrigation line coming directly from the pump. Many use it to connect hoses and pipes, as it is flexible and allows for non-linear connections. Many farmers also use it as the header line in the field, to which nozzles or lines of drip tape are attached.

Aluminum pipes are also lightweight, and less prone to leaks. Many farms use aluminum pipes as the header line in each field. Some farms also use them as their primary irrigation lines across the farm.

PVC and HDPE are inflexible plastics that are sometimes used for primary irrigation lines. This is especially common for buried irrigation lines; in these systems, there are multiple locations across the farm where the buried line emerges, and farmers can connect above ground layflat or other types of irrigation lines to the buried primary line in order to bring irrigation to each field. PVC must be “blown out” each fall with pressurized air to prevent water from freezing in the pipes and cracking them. HDPE is a more flexible plastic that can withstand some freezing.

Filters and backflow prevention

All irrigation systems should have filters to remove sediment and other debris. The correct filter for a given system will depend on the expected amount of sediment, the water pressure, and the size of the irrigation lines.

For growers who inject fertilizer, acids, or any other chemicals into their irrigation water, backflow prevention is required to prevent contaminating the water source. Like filters, the correct backflow prevention device will depend on the water pressure and the size of the irrigation lines.

Equipment for fertigation and pH modification

Many growers apply soluble fertilizers through their irrigation, especially in high tunnels. Some growers may need to reduce the pH of their water if it is basic. The same injection equipment can be used for both of these purposes. An injector works by taking concentrated solutions from containers or tanks and adding them into the main water line.

Any fertilizer injector should be paired with a backflow prevention device to prevent fertilizer or other chemicals from entering the water supply. An injector allows you to pull liquid from a container into your irrigation line. They can be used with liquid fertilizers or acids.

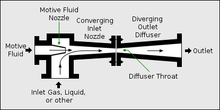

Venturi-style injectors are simple and affordable tools for adding fertilizer and acids to irrigation water.

- You attach the water hose to one end, and another receiving hose to the other, and the injector creates a pressure difference.

- A container with liquid fertilizer or acid attaches to a third attachment site in the middle of the device, and the liquid is pulled into the water stream via suction.

- You can adjust the pressure differential between the inlet and outlet sites, which changes the rate of suction. This allows you to change the concentration of the fertilizer or acid solution entering the water stream.

While most Venturi-style injectors come with instructions, growers will need to do some trial and error to get the right concentration of the final solution. They also do not account for changes in flow rate or water pressure, and so they cannot provide precise control.

There are many models of Venturi-style injectors; choose the correct model based on the flow rate of your irrigation system.

Volumetric proportioning injectors (Dosatron, MixRite) are much more expensive than Venturi-style injectors, but they are also more precise.

These injectors use hydraulic motors to pull liquid (fertilizer or acid solution) from a container or tank into the waterline. This means they are powered by the water flowing through them, and they do not require a power source. They maintain a consistent concentration, even if the flow rate or pressure of the water main line changes.

They can also be set to a specific concentration (1 part solution to 10 parts water), which reduces the trial and error work for the user.

Because these injectors have moving pieces, they may need to be serviced more often than the more low-tech Venturi-style injectors.

These injector systems are common in high tunnels, especially among growers who use fertigation (fertilizing with water-soluble fertilizers through irrigation water).

For small-scale growers (about 5 acres or less), or growers who want to use a small amount of water-soluble fertilizer on just a field or two, very simple injector systems can be used.

These systems are similar to Venturi-style injectors: they consist of a ball valve connecting two hoses. The ball valve coupling has barbed fittings on either end, which attach to tubing, connecting the water line to a small container (usually 0.5 to 2 gallons) with a liquid or water-soluble fertilizer.

You can set the flow rate. While this system is not precise, it allows for a range of flow rates from low to high. Water from the mainline is diverted directly into the container, where it mixes with the fertilizer solution, and then enters back into the main irrigation line.

While these systems do not allow for a precise concentration or ratio of fertilizer to water, they work well when you want to apply a certain amount of product per acre, because you can simply add the desired amount to the tank and run it until it is gone.

Reviewed in 2022