Minimize storage losses with these strategies for storing wheat and barley.

The first step in good stored grain management is to thoroughly clean bins and handling equipment three to four weeks before harvest.

Old grain and fines under perforated floors, in aeration ducts, in grain handling equipment and inside and outside grain bins are likely to be contaminated with insects. By removing this material, you can avoid immediate infestation of the new crop. Consider fumigating any areas that can't be cleaned.

After cleaning the bin and equipment, consider spraying the bin with an approved, residual-type insecticide.

Insects and molds are less active in dry grain.

When storing wheat for less than six months, make sure it’s 14 percent moisture or less. When storing for more than nine months, make sure wheat is 13 percent moisture or less. Barley should be about 0.5 percentage points drier than these values.

If you’ll store grain into next summer or often have problems with insects, consider applying a grain protectant as you move the crop into storage. Contact potential buyers to see if they’ll accept treated grain—some won’t.

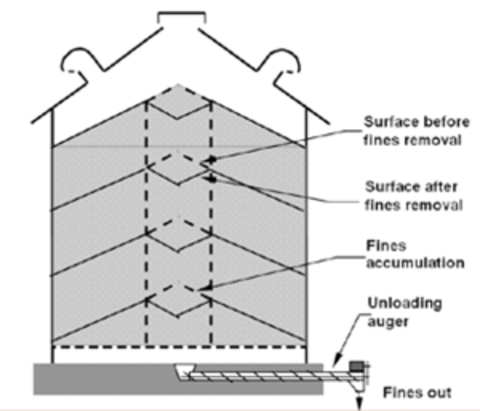

Fines tend to congregate in pockets within storage bins. They restrict airflow, and are more susceptible to molds and insect attacks.

Try to limit the amount of fines in storage by:

Setting combines for minimum grain damage and maximum cleaning.

Slowly operating grain augers.

Filling augers with grain to reduce kernel breakage.

Cleaning grain before storage to remove fines.

Either use a grain spreader to fill bins and uniformly distribute fines throughout the grain mass, or don't use a spreader and periodically remove fines that accumulate in the bin’s center during filling (Figure 1).

Why to keep grain cool

Keeping grain cool reduces mold and insect activity. Activity slows at temperatures below 60 degrees Fahrenheit and almost ceases below 40.

Because daytime temperatures usually exceed 60 degrees in late summer and early fall, you may need to operate fans at night to start the cooling process. Don’t worry too much about high nighttime relative humidity—grain rewetting is unlikely to be a problem.

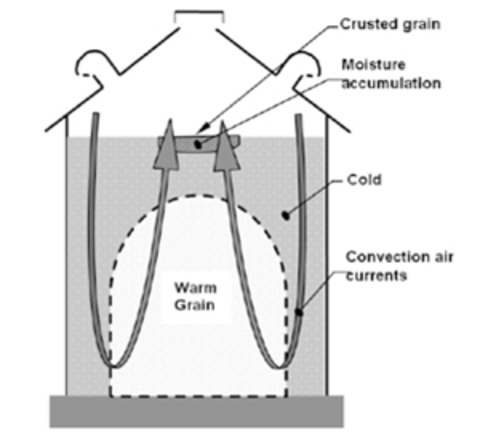

Another reason for aerating grain is to keep its temperature within about 20 degrees of the average outdoor temperature. This prevents moisture migration. If warm grain is stored into cold weather, natural moisture movement from warm grain to cold rewets and spoils grain at the top of the bin (Figure 2).

Recommended storage temperatures

The recommended winter grain storage temperature in northern Minnesota is about 25 degrees. Watch forecasts for 20- to 30-degree weather and operate aeration fans 24 hours a day in late fall to cool grain for winter storage.

How long it takes to cool the grain

The time required to cool a bin of grain depends on the airflow per bushel provided by the aeration fan. The recommended aeration rate for farm bins is 0.1 cubic feet of air per minute (cfm) per bushel of grain in the bin.

The rule of thumb for how many hours it takes to cool grain is 15 divided by the aeration rate in cfm per bushel. If the aeration rate is 0.1 cfm per bushel, approximate cooling time is 15 divided by 0.1, which is 150 hours.

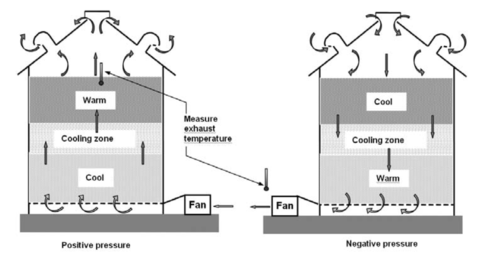

However, the only way to for sure know that cooling is complete is to actually measure the temperature of the grain or the air exhausting from the grain (Figure 3). If grain isn’t cool enough after a cooling zone has completely moved through the bin, repeat the aeration cycle when the weather gets colder.

You don’t need fully perforated floors to aerate dry stored grain—simple duct or pad systems are adequate. You can use either positive or negative pressure systems to aerate dry stored grain.

Whether to warm grain in the spring is a controversial question. The answer seems to depend on how far you cooled grain during the winter and when you’ll unload the bin. The colder grain is, the more likely condensation will occur during storage or handling in warm weather.

If you cooled grain to less than 25 degrees Fahrenheit during winter and will keep it until summer, aerate the grain in early spring to warm it to 40 to 50 degrees. However, if you’ll feed or sell grain by summer or if its temperature exceeds 25 degrees, you probably don’t need aeration to warm the grain.

How to check stored grain

Check stored grain monthly during cold weather, and every two weeks during warm weather. Look for evidence of mold on the surface and in probe samples.

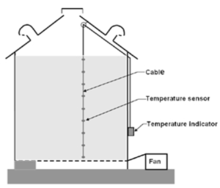

Also, use probes and insect traps to check for insects. Measure and record temperatures at several locations and watch for spontaneous heating—a sure sign of mold or insect activity. Permanently installed temperature cables make this job a lot easier (Figure 4).

Also, briefly start the fan on cool, dry days and smell the first exhaust air leaving the bin for musty or sour odors.

What to do if you find problems

If you find storage problems, try to use the aeration fan to reduce the grain temperature. If the problem is mold and cooling doesn't solve the problem, move, redry, feed or sell the grain as soon as possible. Be sure to check moldy grain for mycotoxins before feeding it.

Keep in mind it’s illegal to use bleach or another chemical to hide a musty odor. Also, breathing mold spores can cause both short- and long-term health problems, so make sure you wear a respirator or dust mask that’s designed to filter mold spores or other toxic dusts.

If insects are causing the problem and the outdoor temperature is above 50 degrees Fahrenheit, consider fumigating the grain. Because fumigants are dangerous chemicals, we recommend hiring a commercial fumigator. Fumigants don’t provide any residual protection against insects, so if grain is warm, damp or moldy, insects will reappear as soon as the fumigant dissipates.

Reviewed in 2018