Here, you’ll find guidance about two methods of cooling corn after drying – dryeration and in-storage cooling – and strategies for successfully drying grains for harvest.

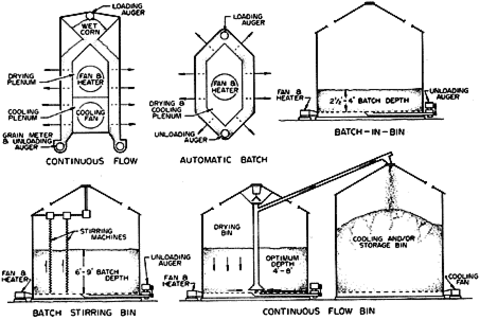

The typical high-speed drying process rapidly reduces corn moisture content using heated air and then rapidly cools the corn in the dryer before transfer to storage (Figure 1).

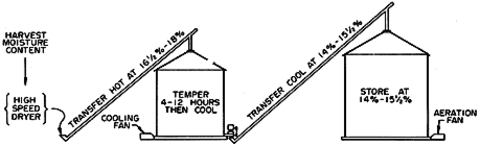

Dryeration (Figure 2), a process developed at Purdue University in the late 1960s, modifies this high-speed drying process by transferring hot corn to a cooling bin, eliminating in-dryer cooling. Advantages include increased dryer capacity, reduced fuel consumption and better corn quality.

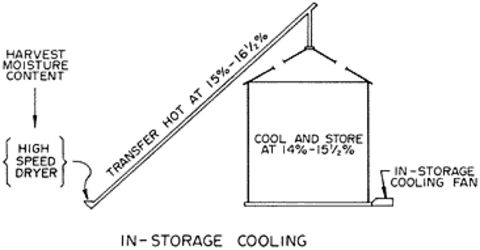

In-storage cooling (Figure 4) is an alternative to in-dryer cooling. Hot corn is directly transferred to the storage bin rather than a special cooling bin, as in dryeration. In-storage cooling eliminates the extra handling step that is sometimes a disadvantage of dryeration, making in-storage cooling a feasible alternative.

Dryeration

In the dryeration process, hot corn is delivered from a high-speed dryer to a dryeration bin, where it tempers, or steeps, without airflow for at least four to six hours before being slowly cooled. Figure 2 shows the steps involved.

The high-speed dryer’s capacity is increased because the dryer is not used for cooling. A batch dryer eliminates cooling time, and adding a burner to the cooling section of a continuous-flow dryer converts the entire dryer column to full heat.

Immediately after high-speed drying, the kernels’ inner portions are wetter than its outer portions.

While the tempering process equalizes moisture throughout the kernel, the slow-cooling process following the tempering period removes two to three percentage points of moisture. By contrast, rapid in-dryer cooling removes little water.

Increased capacity and efficiency

Because dryeration uses the heat contained in the corn to remove water during cooling, it requires requires less fuel and increases a high-speed dryer’s capacity.

Dryeration also minimizes the kernel stresses developed in final stages of high-speed drying and rapid cooling. Improving kernel quality produces corn that’s less susceptible to stress cracking and damage during subsequent handling operations.

When using a high-speed dryer for dryeration, you can increase the drying air temperature. This is possible because the corn is discharged at a higher moisture content and spends less time in the dryer.

Increasing the drying air temperature further increases the dryer’s capacity and fuel efficiency. When increasing the drying air temperature, carefully monitor the corn quality (test weight and stress cracking) to ensure it maintains satisfactory quality.

Typically, dryeration leads to energy savings of 20 to 40 percent and increases dryer capacity by 50 to 75 percent. The actual energy savings and capacity increases primarily depend on the initial corn moisture content. Weather conditions and corn temperature also affect energy use and capacity.

Post-cooling considerations

After cooling has been completed, transfer corn from the dryeration bin to aerated storage.

Corn that has gone through the tempering period in the dryeration bin should not be left there for storage. That’s because, during the tempering period, condensation can build up in the corn next to the bin wall and lead to spoilage.

If using the dryeration bin to store the last corn dried, follow the recommendations for in-storage cooling.

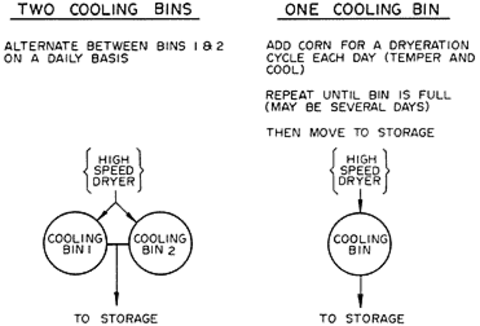

A separate cooling bin (or bins) is necessary for the dryeration process. Arrange the dryer and cooling bins so it’s easy to switch bins and transfer cooled corn to storage, as shown in Figure 3.

The best arrangement is to provide two cooling bins, each holding at least 24 hours of drying capacity. Deliver hot corn to a bin throughout the day and allow it to steep with the cooling fans off.

Process

Once the first hot corn delivered to the bin has steeped at least four to six hours, turn on the cooling fan while delivering additional hot corn to the bin. Typically, cooling fans should start in the evening if hot corn is first delivered to the bin in the morning.

On the second morning, switch the dryer discharge to the second dryeration bin. During the second day, complete cooling in the first dryeration bin and transfer the corn to storage. Alternate the dryeration process from bin to bin on each succeeding day.

With larger-capacity cooling bins, more than one day's drying can safely be accumulated before transfer to storage. If the maximum benefit is to be obtained from dryeration, adjust the cooling fans so all hot corn has a four- to six-hour tempering period.

Using one cooling bin

If only using one cooling bin for dryeration, it should be large enough to hold several days’ drying capacity.

Hot corn is delivered to the bin, allowed to temper and then cooled on a daily basis. Each day, add more hot corn to the bin. Again, to provide the maximum benefit from dryeration, the cooling fan should provide at least a four- to six-hour tempering period for all hot corn. This always requires some initial checking and experimentation on the specific cooling rate of the fan-bin system.

Control the cooling fan with a 24-hour timer or a one- to two-hour percentage timer. A percentage timer control allows operators to adjust the fan operating time to any percentage of the total period.

When using only one cooling bin, there are several methods for finishing the cooling and transferring corn:

Shut down the dryer while completing cooling and transferring corn. These steps take considerable time, reducing the drying system’s overall capacity.

Operate the dryer normally with in-dryer cooling and directly transfer the corn to the storage bin while cooling completes for the hot corn in the cooling bin. Do not deliver cooled corn on top of hot corn in the cooling bin, since moisture from the hot moist air will condense on the cooled corn. After cooling has been completed, deliver cooled corn from the dryer to the cooling bin as it’s unloaded.

Deliver hot corn from the dryer to the cooling bin as the transfer to storage occurs. This generally should be avoided. However, it can be satisfactory if delivering the hot corn at a much lower rate than the rate it’s being unloaded from the cooling bin – for example, when delivering from a continuous-flow dryer to a cooling bin with high-capacity unloading. Aeration in the storage bin will adequately cool the corn. Do not use this method with a high-unloading capacity batch dryer.

Completely unloading a flat-bottom bin is not necessary if the corn remaining in the bin stays cool, dry and in good condition. However, completely empty the cooling bin before filling it the last time for storage.

The dryeration system’s success depends on good design and equipment selection, including:

Adequate capacity in the cooling bins and air delivery systems.

Properly sized cooling fans and air delivery systems.

Well-coordinated handling systems with adequate capacities.

Size the cooling bins to hold at least the maximum 24-hour capacity of the high-speed dryer. Remember that when used in dryeration, high-speed dryer capacity will drastically increase (50 to 75 percent).

If you don’t unload the bins each time, deduct the volume of corn remaining after gravity unloading from the bin capacity.

Estimate the bushels of corn remaining in the bin after gravity unloading by multiplying the cube of the bin diameter by 0.11. So a flat-bottom, 24-foot diameter bin would have about 1,520 bushels of corn remaining in the hopper after gravity unloading (0.11 x 243 or 0.11 x 24 x 24 x 24).

Consider long-range needs when setting up a dryeration system. A cooling bin set up today to handle the capacity of a eight-row combine may be required to handle a 24-row combine in the future. Extra capacity in the cooling bins is not wasted because you can also use it also for storage.

Growers can equip grain bins with a wide range of airflows depending on what they want to accomplish.

Airflow rates

Storage bins equipped with aeration have airflow rates in the range of 1/5 to 1/20 cubic feet of air per minute per bushel of grain in the bin (cfm/bu). This is enough air to change the temperature of the stored grain as the seasons change and maintain uniform temperatures throughout the storage bin.

Drying bins equipped with full perforated floors and large fans have airflow rates in the 1 to 1½ cfm/bu range. This is enough airflow to sufficiently dry grain with natural air.

Process

In many cases, aerated storage bins or drying bins can function as cooling bins for dryeration or in-storage cooling. It depends on the airflow rate in the bin and the rate hot corn is delivered to it from the high-speed dryer.

In a dryeration bin, air moves upward, so the first corn delivered to the bin is the first corn cooled. Delaying the start of the cooling fan by at least four hours provides a tempering period.

Then, the cooling fan starts and the dryer continues delivering hot corn to the bin. Cooling and drying continue at the same time. Do not cool the hot corn delivered to the top of the bin before tempering it for at least four to six hours.

When the bin is full or drying is stopped, it should take at least four hours to finish cooling the corn. Based on this operating procedure, the fan should deliver enough air to keep up with the dryer.

If the cooling is perfectly matched to the dryer capacity and the fan starts six hours after drying begins, cooling will be completed six hours after drying has been completed.

A minimum airflow rate of 12 cfm for each 1 bushel per hour (bu/hr) of dryer capacity provides cooling capacity to keep up with the dryer.

Select a cooling fan that can deliver this airflow when the cooling bin is full. It’s unrealistic to try to perfectly match the cooling rate with the drying rate.

Cooling proceeds faster at the shallower depths than at the deeper depths because of the higher airflow. Based on experience, growers can adjust the fan’s starting and operating times to ensure all hot corn goes through at least a four-hour tempering period before it’s cooled.

Airflow requirements

The required airflow is based on dryer capacity rather than bin size.

A minimum airflow rate of 4,800 cfm would be required for a dryer delivering 400 bushels of hot corn per hour to the cooling bin (12 cfm/bu/hr x 400 bu/hr). In 24 hours, this dryer would fill a 9,600 bushel cooling bin (400 bu/hr x 24 hours). The cooling fan delivers 4,800 cfm when the bin is full, resulting in an airflow rate of ½ cfm/bu based on the full bin capacity.

On the other hand, if this dryer is delivering to a 19,200-bushel bin, it will take 48 hours to fill it and the same 4,800 cfm keeps up with the dryer. In this case the fan delivers ¼ cfm/bu based on the full bin.

Although a full perforated drying floor is preferable for cooling bins, you can accomplish proper cooling with partial floors or duct systems.

For a partial floor and/or duct system, adequate perforated surface areas and duct sizes are important. Keep air velocities reasonably low to prevent excessive static pressure build-ups and consequent reductions in fan performance.

The air velocities entering the grain through the perforated area should not exceed 25 to 30 feet per minute. To keep the velocities at this level, provide one square foot of perforated area for each 25 to 30 cfm delivered by the fan.

In a duct or partial floor system, air velocities should not exceed 1,500 to 2,000 feet per minute any place it moves through an opening, transition or duct. This requires a free opening of one square foot for each 1,500 to 2,000 cfm moving through the duct or transition.

Any restrictions – such as flanges, braces, floor supports, etc. – will increase the velocity and create an additional static pressure build-up.

The additional grain handling required with dryeration can sometimes lead to bottlenecks.

How to manage transfers

There are three major grain transfer operations in a dryeration system: Unloading wet corn, moving hot corn from the dryer to the dryeration bin(s) and moving cooled corn from the dryeration bin(s) to storage.

This is one more transfer operation than what’s normally required with a conventional operation. Sometimes the extra transfer step can be handled by intermittently operating the three steps with the existing transfer equipment.

This may mean shutting down one or more transfer operations while transferring cooled corn from the cooling bin to storage. In this case, high transfer rates are required to avoid long periods of downtime for the other operation.

In other situations, producers may add extra materials-handling equipment, such as a second leg, allowing for continuous transfer at slower rates.

Factors to consider

The extra transfer operation may be a particular concern when only using one cooling bin, since it’s important to rapidly empty the cooling bin so the drying operation can continue. Each installation is different, but it’s important to consider grain transfer in developing a dryeration system.

It’s also important to note the capacity of some materials-handling equipment, such as augers, decreases when moving wetter, hotter corn. Such corn may not flow well through downspouts at angles less than 45 degrees. This may be a potential bottleneck in moving hot corn from the dryer to the cooling bin.

In-storage cooling

In-storage cooling (Figure 4) is similar to dryeration with one exception: Delayed cooling to allow for tempering or steeping is not recommended. With in-storage cooling, hot corn is delivered to a storage bin equipped with adequate airflow, cooled in the bin and left in storage in the same bin.

If hot corn is delivered to the bin and cooling is delayed, as in dryeration, condensation may build up on the sidewalls and in the adjoining corn.

If this condensation build-up occurs and the corn is left in storage, the wetter corn around the sidewalls may spoil. The problem’s seriousness depends on outside temperature. Cold weather causes more condensation, resulting in more spoilage when the bin walls warm up.

For in-storage cooling, the cooling fans must move enough air to keep up with the high-speed dryer. This means maximum dryer capacity dictates the airflow of the cooling fan or fans, instead of the bin capacity.

Required airflow

In-storage cooling increases dryer capacity by 20 to 40 percent. The necessary airflow is basically the same as that recommended for dryeration: 12 cfm/bu of maximum hourly high-speed dryer capacity.

For existing bins equipped with aeration systems, the aeration fan’s airflow dictates the amount of hot corn that can be delivered to the bin in an hour.

A typical storage bin equipped with aeration will have an airflow of about 1/10 cfm/bu based on a full bin. Thus, a 12,000-bushel aerated storage bin should have an airflow of at least 1,200 cfm when the bin is full.

As a result, you could deliver hot corn to the bin at a rate of 100 bushels per hour (12 cfm/bu/hr x 100 bu/hr = 1,200 cfm). Over a full 24-hour period this amounts to 2,400 bushels and growers can fill the bin over five to six days. If you fill the bin faster than this, you’ll need additional airflow for cooling to keep up with the high-speed dryer.

Other considerations

When using storage bins equipped with aeration duct systems for in-storage cooling, it’s a good practice to first deliver some cool corn to the bin to help prevent possible problem areas between the ducts. Experimenting with a probe thermometer can provide the information for successful operation.

For in-storage cooling, start the fan as soon as hot corn is delivered to the bin and continue running it as long as there’s warm corn in the top of the bin. Once the bin cools to outside temperature, operate the fan for aeration to lower the bin temperature below 35 degrees Fahrenheit in the late fall and early winter.

Strategies for both dryeration and in-storage cooling methods

The general recommendation for grain storage aeration systems has been to move the air downward through the bin and exhaust it through the fan at the bottom.

For dryeration and in-storage cooling, however, it’s recommended to force the air upward through the bin and exhaust it at the top. In most cases, the cooling fans will operate while the high-speed dryer continues to deliver hot corn to the bin.

If using upward airflow, the corn in the lower part of the bin is not subjected to the heat and moisture removed from the last corn delivered in the upper portions of the bin. There will be heavy condensation on the roof and upper portions of the bin walls, particularly in cold weather.

In dryeration, when transferring the cooled corn out of the bin, the small quantity of wet corn around the bin walls will be blended with the rest of the corn in the bin and won’t cause storage problems. Sidewall condensation will not cause problems for in-storage cooling if fans move enough air to keep up with the high-speed dryer and you start them as soon as hot corn is delivered to the bin.

Proper management requires accurate checks on the corn’s moisture content before and after it’s cooled, and on temperatures of hot corn discharged from the dryer and cooled corn in the bin.

Tools to manage cooling

A bin probe thermometer is useful to monitor cooling progress. Temperature cables are highly recommended for monitoring temperatures in bins of 20,000 to 25,000 bushels or larger.

An indoor-outdoor thermometer with one bulb located in the air exhaust from the top of the bin helps when checking cooling progress. However, a low reading on this thermometer does not necessarily mean the bin is cool. The corn in the top center of the bin will be the last to cool and should be checked with a bin probe thermometer. Never stop the fan as long as there’s warm corn in the bin.

How and when to inspect corn

Exercise caution when inspecting bins during cooling of hot corn. The hot, moist air coming off the grain can be hazardous to breathe, and can potentially cause excessive dehydration leading to heat stress problems. Never climb into the bin under these conditions. Exercise care even when looking through the door into the bin, since metal surfaces may be slippery and eyeglasses may fog.

To gain dryeration or in-storage cooling system management experience, check corn temperature immediately after high-speed drying and in the bin during and after cooling.

The best way to check corn temperatures after high-speed drying is to place a sample in a thermos bottle, insert a thermometer and read it as soon as it stabilizes. Leave the hot grain in the thermos until immediately before taking the next sample. This keeps the thermos warm for the next sample.

Electrical moisture testers in common use do not yield reliable moisture contents on hot corn immediately after discharge from the high-speed dryer. Some experimentation is necessary to get reasonably reliable results with these moisture meters.

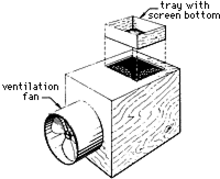

One method is to rapidly cool a sample of hot corn by forcing air through the sample with a small fan, as illustrated in Figure 5.

Moisture corrections

A moisture correction is necessary because some moisture is removed during rapid cooling and because electrical testers may not give accurate readings on freshly dried, cooled corn.

Determine the correction using well-mixed duplicate samples: One rapidly cooled and checked, the other sealed in a moisture-tight container, allowed to cool for 24 hours and then checked. You can also check the duplicate sample via oven drying or the Brown-Duvel oil distillation test.

When managing a dryeration or in-storage cooling system, check the moisture content of the hot corn from the dryer. It’s also necessary to sample the corn in the bin after cooling to ensure it reaches the desired moisture content.

Batch dryers

You can convert batch dryers, both automatic and manual, to dryeration by simply omitting the cooling cycle and unloading immediately after drying.

In some staged batch dryers, you can adjust the proportion of heating and cooling time in the final stage. In these dryers, the final stage is always set for heat.

Continuous-flow dryers

Continuous-flow dryers are generally more difficult to convert to dryeration. Adding a burner unit to the cooling section is perhaps the best way to convert most continuous-flow dryers. This will allow you to operate the dryer normally with in-dryer cooling simply by inactivating the cooling section’s burner.

Some continuous-flow dryers use only one fan unit to deliver air to both the heating and cooling section. In these dryers, a burner can be added to the air stream going to the cooling section. Sometimes removing the divider between the heating and cooling sections and rearranging the diverter to the cooling section provides a satisfactory conversion for dryeration.

In some two-fan continuous-flow dryers, particularly those with high airflows (in cfm/bu), you can achieve satisfactory conversion by eliminating the cooling fan and removing the divider between the heating and cooling sections. In low-airflow dryers this may reduce the cfm/bu too much. Also, because the drying fan’s airflow will increase, the burner capacity may not be adequate.

In all cases, converting continuous-flow dryers to dryeration should only be done by the manufacturer or after consulting with the manufacturer. The manufacturer should be able to provide recommendations on dryer performance and operation safety after the conversion to dryeration.

With both dryeration and in-storage cooling, hot corn must be handled by augers, legs and downspouts out of the high-speed dryer.

How condensation occurs

Condensation can occur in this equipment, particularly in colder weather. Condensation in the trunk of a bucket elevator may run down into the boot and freeze. Continually check equipment for serious condensation accumulations. Periodically cleaning elevator boots, hoppers and other equipment will help minimize these problems.

When delivering hot corn to a bin through a downspout, warm moist air may move up the downspout and condense. This condensation may run back down into the bin or, if condensation occurs in the elevator head, it may run into other bins through its downspouts.

What to do

A manual- or gravity-operated flapper valve at the end of the downspout near the bin prevents air from moving up the spout and will help minimize the problem.

You can eliminate downspout condensation problems by installing exhaust fans in the roof of the bin that will move 25 to 50 percent more air (at 1/8 to 1/4 inch of water static pressure) than the cooling fan. Exhaust fans operating at a slight negative pressure (1/8 to 1/4 inch of water) will keep the top of the bin under a slight suction, preventing warm moist air from moving up the downspouts.

Another solution could be to pressurize the downspouts using a small fan to force air down the spout into the bin.

Warning: Flowing grain is dangerous

Never enter a grain bin or other grain storage area while the grain is flowing. Flowing grain will exert forces against the body great enough to pull the average-sized person under the grain in only a few seconds, leading to death by suffocation.

Reviewed in 2018