Quick facts

- Composting is an approved method for disposal of poultry, swine, cattle, horses, sheep, goats and farmed deer.

- Always check with local authorities to understand local rules and processes before starting a mortality compost system.

- The method you use to compost depends on the carcass size, number of carcasses and space available.

- In the case of animal deaths due to disease outbreaks, you must take additional biosecurity measures.

Composting is a widespread practice for many types of organic materials that can be adapted to handle dead livestock. While many of the aspects and processes in mortality composting echo the composting of other organics, one key difference is how time factors into an efficient and successful process.

Composting is one of many methods approved for disposal of poultry, swine, cattle, horses, sheep, goats and farmed deer by the Minnesota Board of Animal Health under normal operating conditions. Composting is also recognized as an option for animal mortality plans that are part of permits through the Minnesota Pollution Control Agency. Always check with local authorities to understand local rules and processes before starting a mortality compost system.

Mortality composting is also an option for mass animal deaths caused by disease outbreaks or when quickly depopulating a farm. In the case of disease outbreaks, you must take additional biosecurity measures.

In any situation, the Minnesota Board of Animal Health will help producers determine if composting is an appropriate disposal method and if there are any specific farm considerations for the composting process.

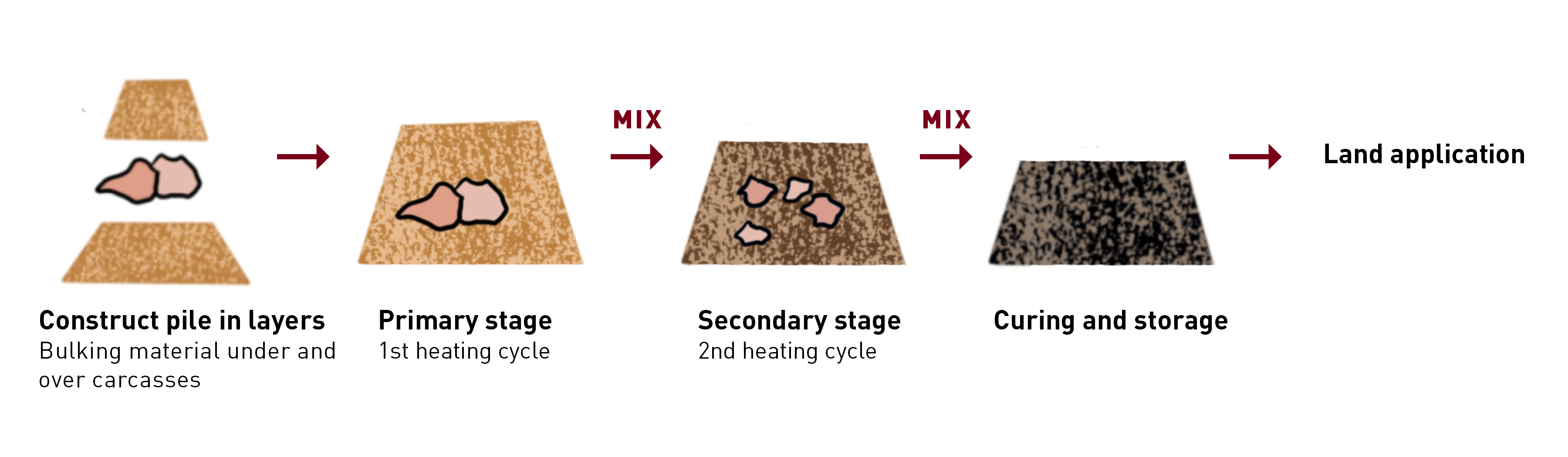

Mortality composting process

Composting is the conversion of organic material to carbon dioxide, water, heat and a stable humus-like product through aerobic (oxygen-aided) processes. With mortality composting, there are key stages to complete this process.

- The primary stage (1st heat cycle) is for the breakdown of soft tissue and softening of bones.

- The secondary stage (2nd heat cycle) furthers the breakdown process.

- The curing process finishes the breakdown process at lower temperatures.

Two heat cycles are necessary. Monitor the internal temperature of the pile with a temperature probe to track the composting process.

- Make sure temperatures over 130°F are reached and maintained for 7 to 10 days in both the primary and secondary stages.

- A good indicator for the end of the primary and secondary stages is when the temperature rises sufficiently and then cools to ambient air conditions.

- Mixing after the first and second stages restarts the composting process by redistributing nutrients, moisture and air through the pile.

- Finished compost has a dark, humus-like appearance, with no evidence of flesh or tissue.

- Bone fragments should be minimal and very brittle.

- Additional screening of finished compost prior to land application is recommended.

- Compost should be applied according to a nutrient management plan.

The primary and secondary stage time depends on the mass of the largest intact carcass, as well as weather conditions and management. Opening a carcass can speed up the process. The below chart shows some approximate timelines to be aware of.

Approximate timelines for primary and secondary composting stages

| Consider the largest, intact animal size | Primary stage | Secondary stage | Curing | Total time |

|---|---|---|---|---|

| Beef cow (~ 1500 lbs) | 90 - 180 days | 60 days | 30 days | 6 - 9 months |

| Horse (~ 1000 lbs) | 75 - 160 days | 50 days | 30 days | 5 - 8 months |

| Sow (~ 500 lbs) | 60 - 120 days | 40 days | 30 days | 4 - 6 months |

| Finishing pig (~ 300 lbs) | 45 - 90 days | 30 days | 30 days | 3 - 5 months |

| Nursery pig (~ 50 lbs) | 20 - 35 days | 12 days | 30 days | 2 - 3 months |

| Anything 3 lbs or smaller | 10 days minimum | 10 days | 30 days | 2 months |

You must be prepared to devote the time and space to the process. Questions to ask yourself when selecting a compost site include:

- Is the location accessible and available for the required total time?

- Is there water access?

- Can you easily move equipment?

- Do other farm operations need to shift because of the compost pile size or location?

- Will the sight of the compost pile be an unwelcome reminder of a challenging time or loss?

When planning a space for composting, plan for three areas within the space.

- One for primary stage composting.

- A second for secondary stage composting.

- A third for curing or additional space for bulk materials.

This allows for a continuous flow of mortalities under normal operating conditions.

Always check with local and state rules on whether there are restrictions on where composting occurs relative to groundwater or other water sources. Equipment accessibility and maneuverability around the site and pile, water availability, and visibility are other factors.

Under normal operating conditions, the estimated space requirement depends on your typical daily death loss.

Calculate the daily death loss using an annual mortality rate:

- Daily death loss, in pounds per day = (Average animal mass, in pounds per animal) x (Average number of animals on farm) x (Annual mortality rate, in %) / (100 * 365)

Based on the largest individual carcass size, multiply the daily death loss by the volume shown in the table. This is the volume required for the primary stage storage space.

The secondary stage storage space should be the same size.

Curing is approximately 1/3 of this, plus some additional space for bulk materials.

Three bins or areas of the same dimensions is a common layout.

Volumes to multiply daily death loss by based on carcass size

| Carcass size (lbs) | Multiply daily death loss by |

|---|---|

| 0-10 | 3 ft3/lb |

| 10-25 | 5 ft3/lb |

| 25-300 | 10 ft3/lb |

| 300-750 | 14 ft3/lb |

| 750-1400 | 20 ft3/lb |

For a bin approach, consider equipment width for adding material and carcass. The bin area should fall between 100 and 400 square feet.

In a windrow approach, the windrow width should be the head-to-rear length of the largest carcass, plus 2 additional feet on each side.

Materials and equipment

Besides time and patience, key resources for successful mortality composting include bulking material (also called carbon amendment), a water source, equipment, fencing and monitoring equipment.

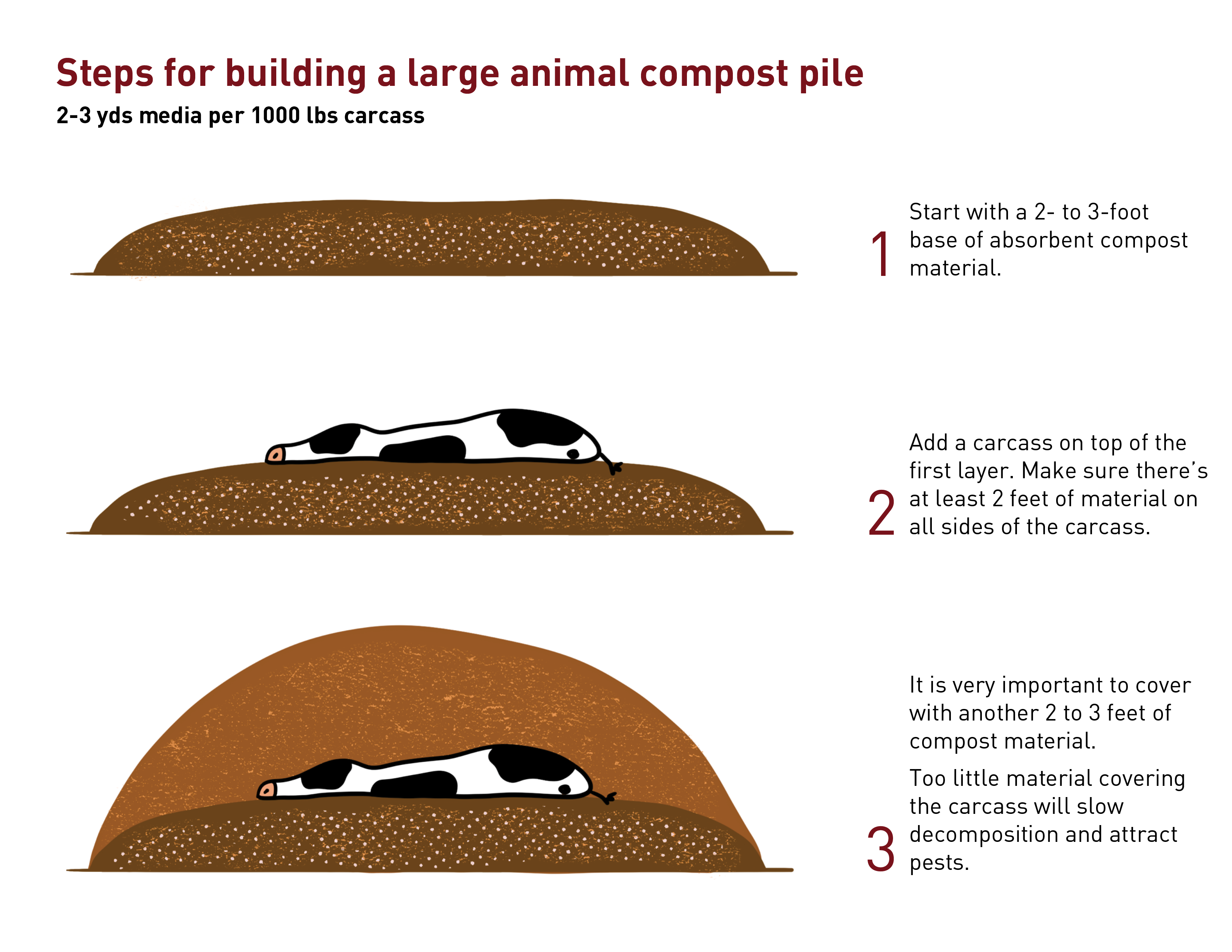

The general rule of thumb is that 3 to 5 yards of media accompany 1000 pounds of animal mass.

A mortality composting pile has two parts when it is initially set up:

- The media bed, on which the carcass material is placed.

- The cover material.

The material for the media bed and cover material is a source of carbon for the composting microbes, which should retain moisture and porosity. Mulch, wood shavings, and crop residue are popular options.

Sometimes a mixture of sources works best for the media bed, to achieve some moisture-holding capacity. For example, while straw and corn stalks are great carbon sources with high porosity, their surfaces tend to shed water.

Chopping and mixing either of these with some compost or sawdust provides a good mixture of both moisture and porosity.

- There should be 2 to 3 feet of media bed under the carcass, and 2 to 3 feet above and around the carcass after placement.

- The cover material serves as an additional odor barrier. The cover material is likely to settle after about one week. During construction, set aside some extra cover material to cover cracks or cave-ins that develop.

- If there is no roof or rain protection for the compost, water-shedding material may be a better option for the exposed surface of the mortality pile, to reduce precipitation entry into the pile.

The Minnesota Board of Animal Health provides a list of contacts for carbon sources.

Water Source

Composting is efficient and effective when the moisture content is around 50%.

- The compost material should leave your hand feeling moist, but you should not be able to squeeze any water out of it.

- For a mass mortality pile, consider ways to add moisture if rainfall is not sufficient.

- Options may include a water truck or soaker hose.

Equipment

The right equipment makes any job easier. A loader will aid in pile construction and will also be needed for turning and mixing the pile after the primary and secondary stages.

Fencing

Scavengers and pests can be an issue if the odor is not contained. Ensuring adequate cover over the carcass(es) is the best prevention. However, temporary fencing around the perimeter or access points can reduce access, while still allowing equipment entry when necessary.

Monitoring equipment

A temperature probe is highly recommended. Choose a temperature probe with sufficient stem length to reach the carcass or near center point of the pile. This may be greater than 24 inches for large animal composting.

- A daily temperature record for primary and secondary stage piles helps track progress and action occurring at the center of the compost, which is invisible to someone watching from beside the pile.

- A record may be simply recording the temperatures on a calendar or could include a more extensive datasheet.

- Recording other actions, such as the date of the last carcass placement, mixing, rainfall and water additions will help hone the process for an operation over time, with experience.

- Temperature monitoring is a requirement for some permits and programs.

Compost systems

There are various configurations for mortality compositing, depending on the carcass size, mortality addition rate and space availability. Use or retrofit of older buildings and sheds is a consideration, particularly if there is sufficient access for machinery. Design assistance is available.

Advantages

- Can be built in various places, including in a pasture.

- Lower initial cost than facilities or special equipment.

Disadvantages

- Exposure to wind and rain.

- Increased risk of leachate.

- Scavengers.

Advantages

- Looks neat and contained.

- Risk of leachate reduced with a roof cover or concrete pad beneath.

- Reduces access points for scavengers.

- Moisture and rain may be easier to control.

- Opportunity to modify existing sheds or barns for this purpose.

Disadvantages

- Higher initial investment.

- Water source needed.

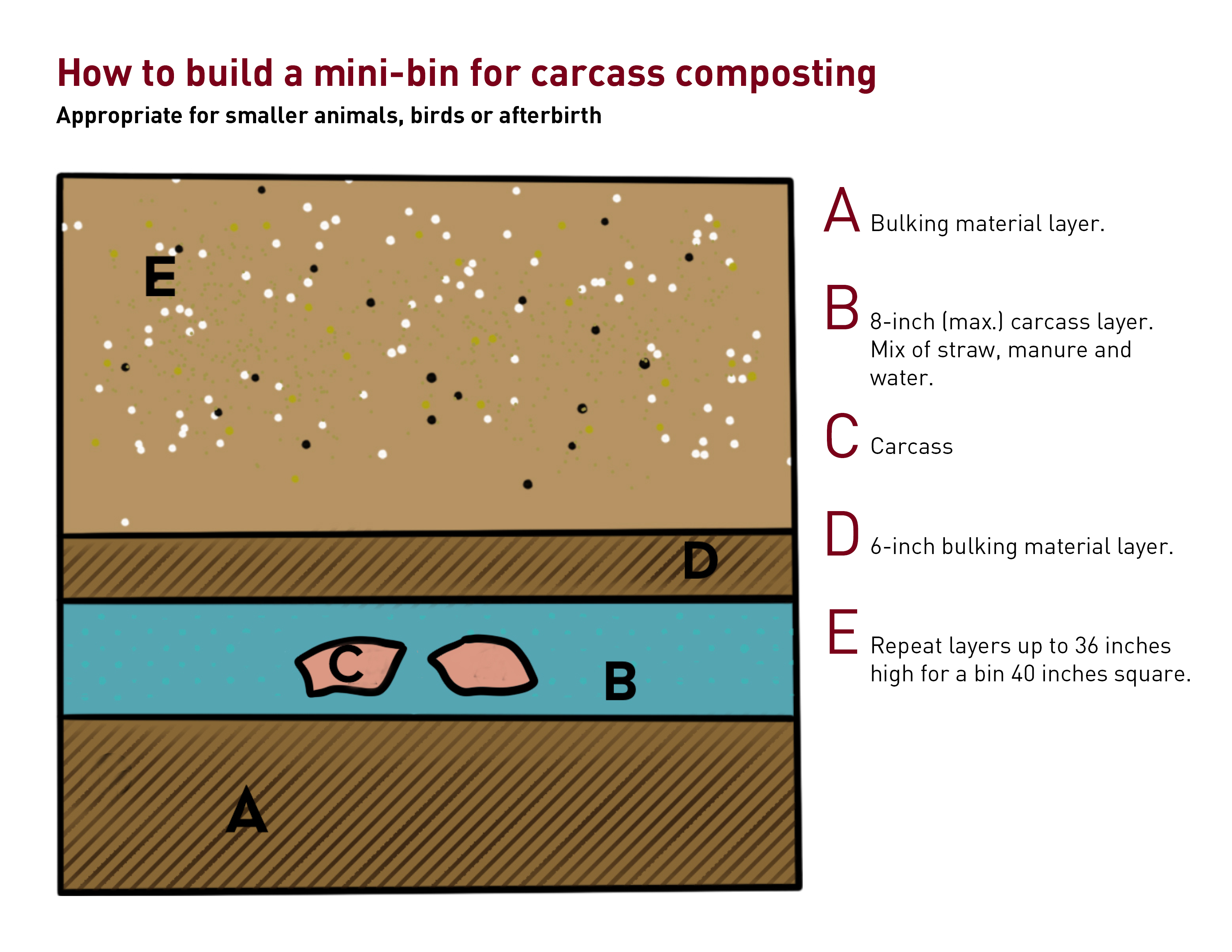

Advantages

- Appropriate for smaller animals, birds or afterbirth.

- Fast degradation due to carcass size.

- Low cost.

Disadvantages

- Inability to hold heat in cold conditions.

Advantages

- Promotes mixing, heating and faster breakdown of organic material.

- Quicker composting.

Disadvantages

- Higher capital and operating costs.

Resources for setting up mortality composting

Additional resources for emergency carcass disposal

- MN Board of Animal Health Emergency carcass disposal resources during COVID-19

- MN Pollution Control Agency Guidelines for Livestock Carcass Disposal

- USDA-NRCS Emergency Milk Disposal and Emergency Animal Mortality Management

- USDA-NRCS Funding available to help with emergency livestock mortality

Reviewed in 2020