Uniformly applying herbicides at proper rates is essential for effective weed management. A slight variation in the application rate with some chemicals may result in poor control of the pest or injury to the crop or environment, causing lost time, effort and money.

How to calculate

Herbicide rates may be given in terms of active ingredient or acid equivalent per acre treated, or as pounds or volume of commercial product per acre.

Active ingredient indicates the amount of non-acid herbicide in a formulation. Acid equivalent indicates the amount of an acid herbicide in a formulation.

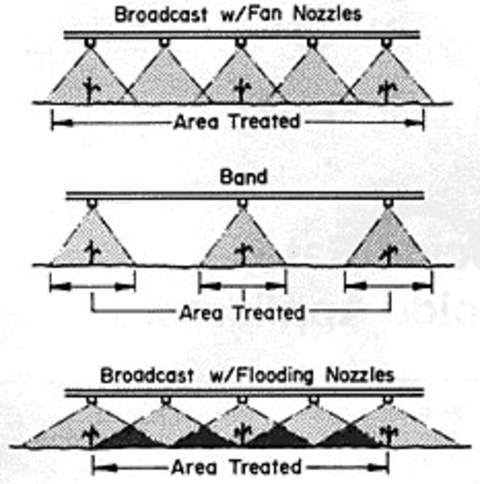

Herbicides may be applied broadcast (uniformly over the entire field surface) or in bands (narrow strips of herbicide centered over the row, with the area between rows left untreated).

The application rate in the treated area should be the same for both the band and the broadcast application. You can reduce the amount of herbicide needed by as much as two-thirds by banding the application over the row and controlling the weeds in the middle with mechanical cultivation.

For example: A 3-pound-per-acre rate requires 3 pounds of herbicide for each crop acre in a broadcast application, but only 1 pound is needed to apply the herbicide in 10-inch bands on 30-inch rows. To calculate the amount needed for band application, multiply the broadcast rate by the band width divided by the row width.

Commercial products contain different amounts of active ingredients or acid equivalent. The product label may give the amount of herbicide formulation to use per acre. If you have to calculate from the active ingredient amount, use one of the following methods.

Powder

Divide the pounds per acre of active ingredient by its concentration in the product. If 3 pounds of active ingredient are needed per acre, and the product is an 80 percent powder, then divide 3 by 0.80 to get 3.75 pounds, the amount of powder needed per acre.

Liquid

For liquids, the concentration may be given in acid equivalent. Then divide the pounds per acre of acid equivalent needed by the pounds per gallon contained in the product.

For example: If you need 3 pounds per acre of acid equivalent and the product contains 2 pounds per gallon, divide 3 by 2 to get 1.5 gallons per acre. This is how much product you need.

After you’ve calibrated the sprayer to know your application rate in gallons per acre, divide that number into the gallons applied with each tankful to find how many acres each tankful covers.

Then, multiply the acres per tank by the herbicide needed per acre to find the herbicide to put in each tankful.

For example: Assume you have a 30-foot sprayer that holds 500 gallons, and you want to apply an herbicide at 3 pounds of active ingredient per acre. The product comes as an 80 percent wettable powder. You calibrate your sprayer on a 300-foot course and apply 4 gallons of spray to the course.

Your calculations are:

Pounds of active ingredient per acre / concentration = 3 pounds per acre / 0.80 = 3.75 lbs. per acre

(4 gallons per test x 43,560) / (300 feet x 30 feet) = 19.4 gallons per acre

(Gallons per tank) / (gallons per acre) = 500 gallons / 19.4 gallons per acre = 25.8 acres per tank

3.75 pounds per acre x 25.8 acres per tank = 96.8 pounds per tank

For a granular material that’s 50 percent active ingredient

Pounds of active ingredient per acre / concentration = 3 pounds per acre / 0.50 = 6.0 pounds per acre

The applicator must be set to put on 6 pounds of the granules per acre.

Calibration

The sprayer must be set to apply the proper amount of total spray mixture. This is usually given in gallons per acre and is listed with the herbicide recommendations or on the product label. Typical amounts range from 10 to 30 gallons per acre.

To check the distribution pattern across the boom, operate over a smooth, bare area. Set the boom at the proper height above the ground and spray slowly so the spray wets the ground. If you see streaks as it dries, raise or lower the boom.

When the application is even, that boom height is the proper distance to set the boom above your target plants, or ground. If you change nozzles or pressure, check the height again.

To measure the amount applied by the sprayer, follow these steps:

-

Check the output of all the nozzles to make sure they’re flowing at the same rate. If a nozzle is flowing more than 10 percent over its rated capacity, or more than 5 percent above or below the average of all the nozzles on the boom, replace it.

-

With clean water in the tank, set the pressure at the proper level for the nozzles you’re using and adjust the nozzle height for uniform coverage.

-

Spray over a test course in the field at the speed you’ll use while spraying. Note the throttle setting or speed indicator so you can use the same speed later. Note the time it takes to spray the course, in seconds.

-

With the sprayer standing still, operate it at the pressure you’ll be using and collect the liquid from the nozzles over the same time as it took to drive the course and measure the output in gallons.

-

Figure out the gallons per acre: Gallons per acre = Gallons per test x 43,560 / treated area.

Note that area treated is the test course length multiplied by the width; or the course length multiplied by the band width, multiplied by the number of bands.

To measure the output of dry material applicators:

-

Tie plastic bags over the ends of the delivery tubes.

-

Drive the test course with the applicator running.

-

Weigh the collected material.

-

Calculate the rate: Pounds per acre = (Pounds per test x 43,560 / treated area)

Note that treated area is the test course length multiplied by the width; or the course length multiplied by the band width, multiplied by the number of bands. Also, 43,560 is the number of square feet per acre.

If you use a flow meter to measure flow through the nozzle, the meter will show gallons per minute (GPM) for each nozzle. You calculate gallons per acre this way:

Gallons per acre = (GPM per nozzle x seconds per test x 8,712) / (course length x nozzle spacing in inches)

Banding

For banding:

Gallons per acre = (GPM per nozzle x seconds per test x 8,712) / (course length x band width)

Conversion factors

Converting to gallons

| You have | Multiply by | To get |

|---|---|---|

| Cubic feet | 7.48 | Gallons |

| Cups | 0.0625 | Gallons |

| Liters | 0.2642 | Gallons |

| Ounces | 0.0078 | Gallons |

| Pints | 0.125 | Gallons |

| Pounds of water | 0.1198 | Gallons |

| Quarts | 0.25 | Gallons |

Converting to miles per hour

| You have | Multiply by | To get |

|---|---|---|

| Feet per minute | 0.0114 | Miles per hour |

| Feet per second | 0.682 | Miles per hour |

Converting to feet and acres

| You have | Multiply by | To get |

|---|---|---|

| Square feet | 0.000023 | Acres |

| Acres | 43,560 | Square feet |

| Mile | 5,280 | Feet |

| Pounds per acre | 0.367 | Ounces per 1,000 square feet |

| Pounds per acre | 0.023 | Pounds per 1,000 square feet |

| Pounds per acre | 0.0023 | Pounds per 100 square feet |

| Pounds per acre | 0.306 x width | Ounces per 1,000 square feet |

| Pounds per 1,000 square feet | 43.56 | Pounds per acre |

| Ounces per 1,000 square feet | 2.72 | Pounds per acre |

| Ounces per 1,000 feet | 32.67 / width | Pounds per acre |

Reviewed in 2021