Quick facts

- Hand washing is one of the most important things you can do to reduce the risk of contaminating fruits and vegetables with foodborne illnesses.

- Hand sanitizer may be used after handwashing with soap and water, not as a replacement for hand washing.

- Hand washing is an important part of every day on the farm.

- You can build a low-cost handwashing station yourself.

Handwashing is one of the most important steps you can take to reduce the risk of contaminating your fruits and vegetables with foodborne illness-causing pathogens. Many of the diseases that can be transmitted through food may be harbored in the intestinal tracts of people as well as wild and domesticated animals. If a person's hands become contaminated with fecal material, pathogens can be transmitted to fresh produce.

When to wash hands

Wash hands with soap and water before harvesting produce and after breaks, eating, using the toilet, smoking, touching the face, coughing, sneezing, after handling manure or animals or other times you have reason to think that your hands might have become contaminated.

Hand sanitizer is not enough

Hand sanitizer should only be used in addition to proper handwashing, not in place of it. Hand sanitizer is not effective when hands are dirty, and is not intended to replace proper handwashing.

Proper handwashing technique

Wet hands with water (it does not have to be hot).

Apply soap and scrub for 20 seconds. Clean under your fingernails and between your fingers.

Make sure to wash your thumbs, wrists and tops of hands.

Rinse your hands, letting water drip down, not up and over your hands.

Dry hands with a clean, unused paper towel or a cloth towel. Do not reuse hand towels.

Throw towels in a properly covered receptacle.

Handwashing stations on the farm

Where to place handwashing stations?

- Near all portable toilets and in your packing area.

- In packing or storage sheds.

- Near work areas so it is convenient for everyone handling produce.

If your farm is large, consider mounting a handwashing station on a trailer so it can be moved around your farm with workers.

How many handwashing stations do you need?

The Occupational Safety and Health Administration (OSHA) requires one station per 20 employees, but you should have as many as needed to serve everyone who works on your farm. Even if you only have two employees, you should have handwashing stations where they are needed so it is easy for people to wash their hands regularly.

Water for handwashing stations

Handwashing stations must always use clean water that is safe enough to drink (potable).

Standard components of a handwashing station

Handwashing stations should be equipped with the following items:

- A clean enclosed container to hold drinkable water. The container should have a spigot that can be turned on and off, not a push-button spigot.

- Liquid or bar hand soap (does not have to be antibacterial).

- A greywater container to catch the water used to wash hands.

- Single-use paper or cloth towels.

- Covered trash container.

How to build a handwashing station

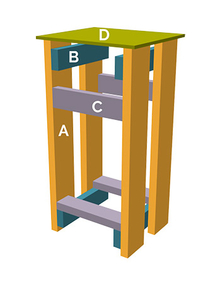

Building your own handwashing station is straightforward and cost-effective. You can purchase lumber or use materials you already have and adjust these plans as needed.

- This stand is about 36 inches tall.

- It uses a 5-10 gallon closed plastic water container with a continuous flow valve and a bucket to catch the wash water.

- Hand soap is placed on the stand.

- Single-use paper towels are located in a plastic dishpan drawer that is built into the stand.

Many dimensions of this stand are based on the size of the dishpan drawer, so measure yours first and adjust as needed.

Step-by-step instructions

You can download these building instructions. Use the download or print icons on the PDF to save to your own desktop or folder.

Safety equipment and tools

- Safety glasses

- Gloves

- Hearing protection

- Pencil

- Tape measure

- Square

- Saw

- Drill

- Drill bits

Materials

-

Lumber

- A. Legs (4) - 2" x 6" cut to 36" long.

- B. Leg connectors (4) - 2" x 4" cut to 15" long, or to fit the length of the dishpan.

- C. Cross pieces (4) - 2" x 4" cut to 14 1/4" long, or to fit the width of the dishpan.

- D. Plywood - 1/2" thick or more, cut to 16" x 18", or to fit the top of the stand with a small overhang.

-

Screws

- 36 - 2 1/2" deck screws

-

Plastic dishpan

- This design uses a 12-quart plastic dishpan, 15" L x 12 3/4" W x 6 1/2" H. Use as a drawer under the water container to hold paper towels.

-

Water dispenser

- With a spigot that can be turned on and off, not a push-button spigot.

-

Water-catching bucket: 5-gallon plastic bucket

-

Trash can: 5-gallon plastic bucket with lid

You'll start with four 2" x 6" legs and four 2" x 4" leg connectors.

- Lay two of the 2" x 6" legs down parallel to each other.

- Lay two of the 2" x 4" leg connectors across the legs.

- Place the top leg connector far enough below the top of the legs to create a lip for the dishpan drawer to slide on. You need to account for the height of the dishpan’s handle, so it fits under the plywood top you'll attach later.

- Similarly, place the bottom leg connector about one inch above the bottom of the legs to allow for uneven ground.

- Use two screws in each end to secure the 2" x 4" leg connectors to the legs.

- Pre-drill the holes to keep the wood from splitting.

- Here, you can see how we placed the top leg connector down from the top of the legs to act as the dishpan drawer slide.

- Repeat steps one and two for the second set of legs.

Stand the legs up and set the dishpan between them, resting the rim on the top leg connectors.

- Measure between the legs to determine the length to cut the 2" x 4" cross pieces. The dishpan should fit snugly, but still easily slide on the leg connectors.

- Cut these four 2" x 4" boards to the length you measured, and hold them in place to be sure of a good fit before screwing into place.

Take two of the 2" x 4" cross pieces and lay them across the lower leg connectors. It works best if you lay these two pieces flat and screw down into the leg connectors.

- Pre-drill two holes near the ends of each cross piece.

- Screw the cross pieces in place with two screws on each end.

With these pieces installed flat, this can be used as a shelf to hold the catch bucket when the station is not in use.

Take the last two 2" x 4" cross pieces and secure them below the top leg connectors.

- Place them low enough so the dishpan drawer fits in the space above. The rim of the dishpan needs to slide on the top leg connectors.

- Pre-drill and screw the cross pieces in place using two screws on each end.

- Measure the top of your stand to determine the size of the plywood top. We recommend at least a 1/2" overhang on all four sides.

- Cut the plywood to fit the top of your stand, and attach it using four screws.

Yours might be a slightly different size than the one here, depending on your materials.

Store the single-use paper towels in the dishpan drawer.

Fill the water container with clean water, and set on top of the stand. Set soap next to the water container.

Put a bucket underneath the spigot of the water container to catch the water. Do not empty the bucket of water in the produce field or where it could be tracked into the produce field.

Keep a lidded trash can handy for the used towels to keep them from blowing away.

Other handwashing station ideas

This is just one idea for a handwashing station. You can make this any size and with any materials. You could use scrap lumber or an existing table or cart. Instead of using the dishpan drawer, you could install a paper towel dispenser under the top. However, the towels might get wet in the rain.

If you take a pickup truck out to the field, you could simply set the water container and supplies on the truck bed and place the catch bucket and trash can on the ground.

Any of these handwashing station ideas can be used in the field, and also at your farmers’ market booth or roadside stand - anywhere you need to provide a place for people to wash their hands.

This handwashing station is based on an original design by Michele Schermann, U of MN Department of Horticultural Science; Annalisa Hultberg, U of MN Extension; and Jill Randerson, Kidzibits, Inc., Minneapolis, MN.

Funding for this publication was provided in part by the Minnesota Department of Agriculture’s Specialty Crop Block Grant Program; by a grant from the U.S. Department of Agriculture (USDA) National Institute of Food and Agriculture Food Safety Outreach Program; and by the Food and Drug Administration through grant PAR-16-137. Its contents are solely the responsibility of the authors and do not necessarily represent the official views of FDA or USDA.

Reviewed in 2020